Nowadays, Tacchi are one of the most appreciated manufacturers of medium and large heavy duty lathes in the world machine tool market.

Our production includes exclusively flat bed CNC heavy duty lathes.

Our models are industry 4.0 compatible, highly customizable, and built for medium to large applications in terms of weight and size.

The CNC lathe is a machine equipped with only two axes, X and Z. Depending on the requirements and the component to be machined, we are able to offer additional units to perform boring, milling, and grinding with a single set-up.

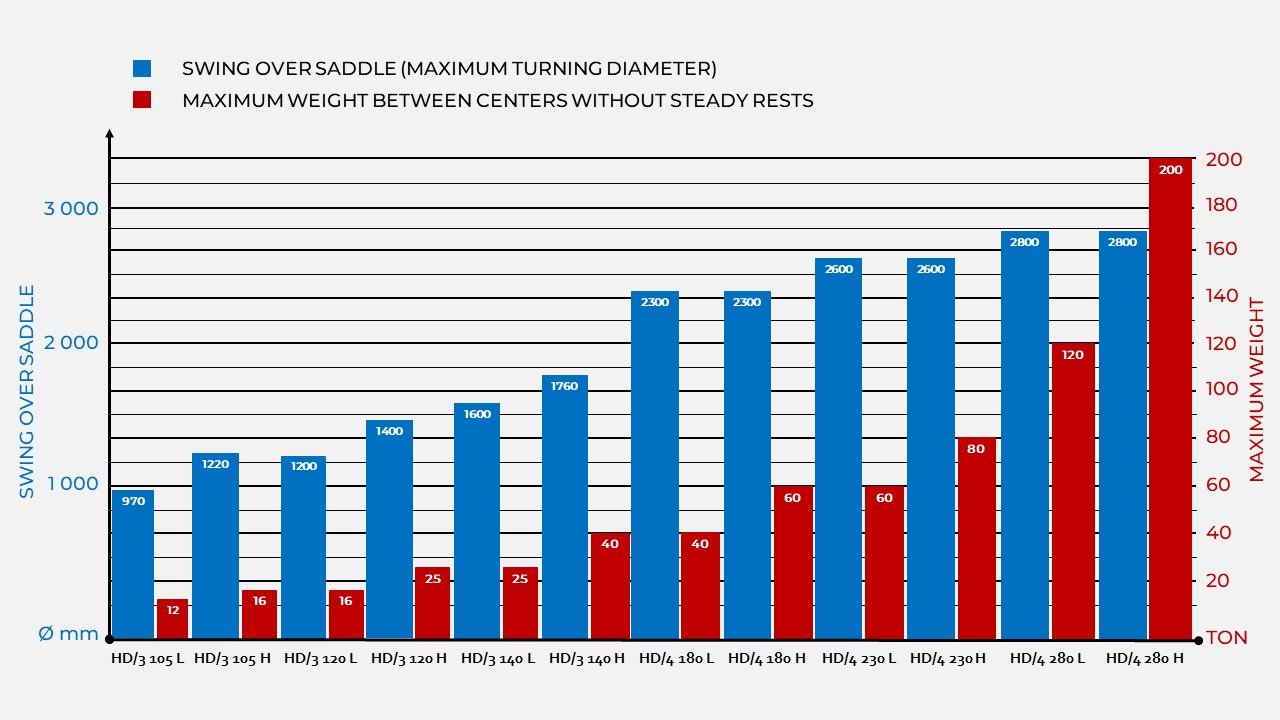

We have in our range machines that can reach 6 meters of turning diameter for a distance between centres that can even exceed 30 meters.

Thanks to our longtime experience, we set no limits for ourselves. We are open to study customer requests and offer the best tailor-made solutions allowing not only turning operations but also boring, milling, grinding and super-finishing.